Battery lifetime extension and VPP support

Infrastructure challenges

Virtual Power Plants (VPP) and other Distributed Energy Resource Management Systems (DERMS) need energy storage solutions to quickly respond to the lack of grid inertia and frequency fluctuation. Lithium-Ion batteries are increasingly used to provide such ancillary services. However, the lifetime and performance of batteries rapidly decrease when they are used in such extremely high-cycling applications that generate battery cell overheating.

Teraloop helps to contain a more stable battery cell temperature, enabling increased bankability of VPP/DERMS investment through additional participation in frequency containment reserve markets and savings on battery replacement.

A more sustainable and profitable system

Our kinetic energy storage systems can enable profitable participation in Frequency Containment Reserves and help to mitigate service interruptions and demand charges, without requiring any major infrastructure upgrade.

They stabilise the output of VPP-integrated renewable sources of energy, such as solar and wind, and reduce the need for back-up generators, contributing to a more sustainable energy mix.

Furthermore, Teraloop´s solutions meet the needs for high-cycling energy storage to efficiently enable peak shaving and fault ride-through (FRT).

The co-location of batteries and flywheels creates a powerful synergy: the flywheel acts as a filter for the battery asset, handling the micro-cycles causing the battery cell temperature increase and their subsequent aging. This results in improved durability of lithium batteries and a more fire safe, bankable, and eco-friendly system.

Advantages

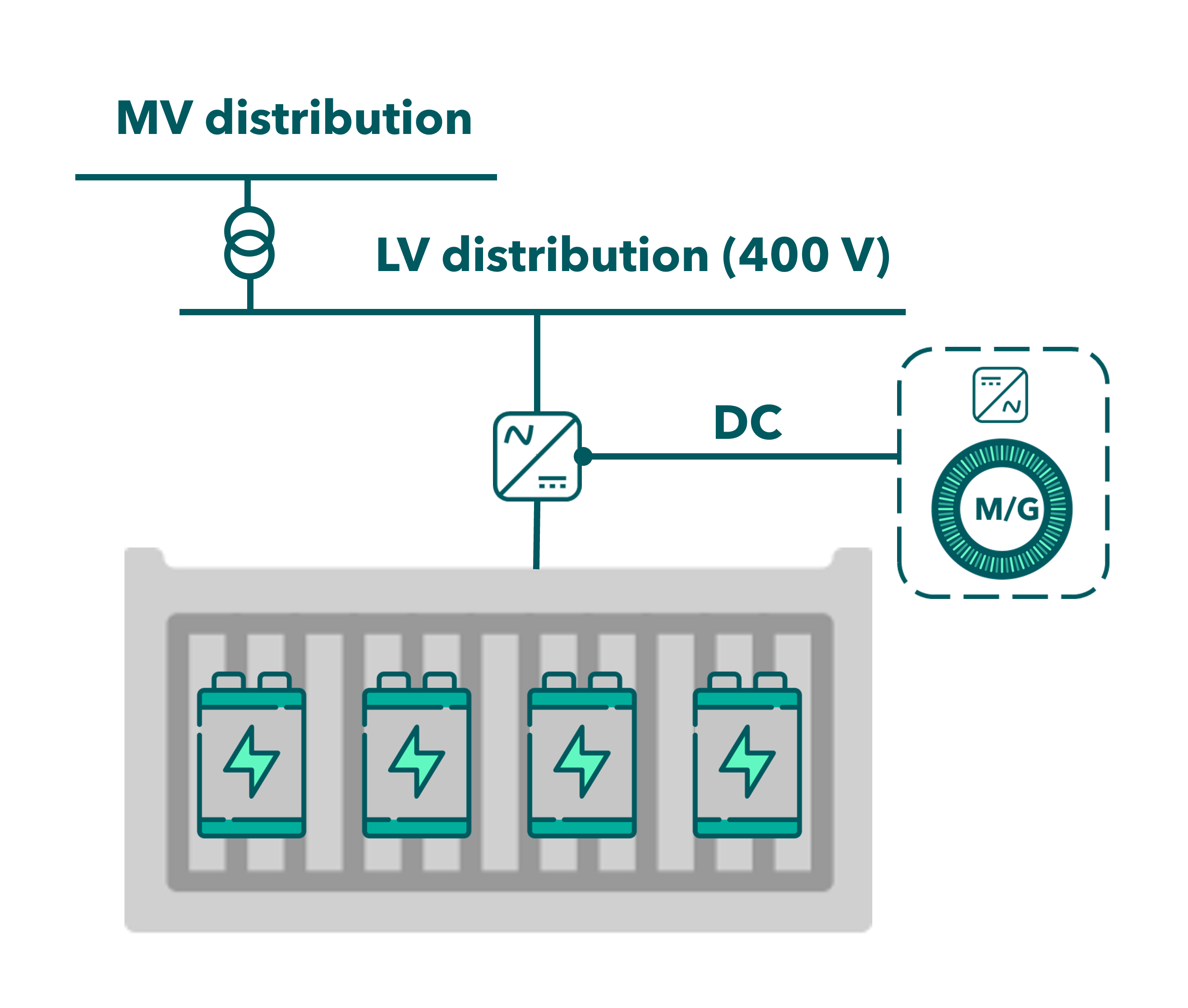

The Teraloop Flywheel is a plug and play solution, managed by the Grid Connected AC Power Converter used by the battery installation. It is connected directly via a DC Link, or AC when more economical.

Our solution is fire safe and helps to keep battery temperature at proper levels.

The system is deployed in partnership with a power system solution provider and tailored to the needs of the customer.

The hardware flywheel energy storage component can operate over 25 years and it is made of recyclable materials.